NEVs Are Revolutionizing Global Mobility — Turck Automates their Production

The automotive industry is currently undergoing a revolution. New energy vehicles (NEVs), customization and modularization require flexible production concepts and smart automation.

For over 50 years, Turck has been driving innovation in automation, also in automotive production. We know the standards and the unwritten rules of this industry. Our Project Management team always has everything under control. Our Sales department knows the automotive world, knows the pain points and always follows the best decision-making paths.

The transformation of the industry is challenging for manufacturers and suppliers alike. Face these challenges with a partner who has been shaping the automation of automotive production for many decades. We have always found creative solutions for the automation of the future.

Smart Production for any Platform

Put your faith in a partner with solutions across the entire automotive market, from tier X suppliers to OEMs, from the press plant to final assembly, and any drive platform you can think of.

Conventional Platform

The classic platform is designed for internal combustion engines including the exhaust system. These platforms can also accommodate electric drives but the architecture remains unchanged. Many automation solutions for classic combustion engines can be transferred to alternative drive concepts.

Multi-Energy Platform

These platforms are designed to accommodate both conventional combustion drives as well as electric or hybrid drives. The production system must be able to cover the different drive types while still maintaining efficiency and availability.

Battery-Powered Vehicles

These platforms are specifically designed to meet the requirements of battery-powered vehicles. Skateboard architecture allows large battery packs to be installed in the underbody and increases the available space while the external dimensions remain the same. Turck provides specialized solutions also for manufacturing batteries.

Turck Knows the Automotive World!

Whether in sales, project management, support, development or production: we have experts who speak your language all over the world .

NEVer Compromise: The Next Level of Automation

Webinar: Decentralized Automation in the Automotive Industry

The Proof Is in the Production Lines

Practical examples for smart automation from the automotive industry

From Shop Floor to ERP: End-to-end IIoT Infrastructure Connects OT with IT

With products at all levels of the automation matrix, we are able to design holistic solutions. Open standards, scalable systems and data access down to the smallest sensor bring transparency and intelligence to your production — cyber-secure even across boundaries between shops and companies.

Products That Bring Performance to the Road

Condition Monitoring

Condition monitoring sensors detect critical environmental conditions, such as humidity, temperature, and vibrations. And the devices from the CCM product series evaluate the data, using the customer's own programming if required.

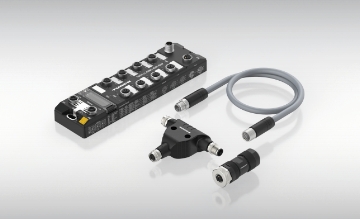

Complete M12 Power Portfolio

Our I/O modules for Ethernet (PROFINET, EtherNet/IP, Modbus TCP, EtherCAT) are equipped with M12 Power supply units as standard. They round off our M12 Power range of junction boxes, connection cables and IP67 power supplies.

Edge Controller and I/O Solutions

Turck provides one of the most diverse ranges of edge controllers, namely controllers with cloud connections, with or without displays. Our IP20 or IP67 I/O solutions also bring logic to the field, fully replacing the PLC or taking over some of its functionality.

RFID Read/Write Heads and Interfaces

Turck's identification systems offer suitable solutions to meet all performance, location and distance requirements. Few other automation partners can handle both production and logistics IDs equally well.

Safety Modules with Integrated Safety Controllers

IP67 block I/Os enable safety functions to be implemented without switch cabinets. Safety applications can be tested offline using their safety controller and controlled in a decentralized way during live operation.

Smart Sensors

Turck's inductive proximity switches are considered to be the de facto standard for bodywork construction in the automotive industry. Our encoders, photoelectric sensors and the Fluid+ series of sensors show that this good reputation is well-deserved.

Ask an Expert

If you have any questions about Turck's solutions for automotive projects, simply use our contact form. Our experts will be happy to help you.

Turck's global automotive team