Automate Your Battery Cell Production

The most successful battery manufacturers rely on Turck technology. Benefit from the data of your automation system for maximum production efficiency and maximum availability with faultless product quality.

The growth of battery production is rapidly accelerating worldwide. This trend is being driven by the energy and mobility transition. One thing is certain: The next 20 years of battery production will be considerably different to the last 20 years.

The processes and technologies for manufacturing battery cells will further develop in the years to come. There will be changes, including new raw materials, modified blending and coating processes or new processes for calendering and winding. But how can battery cell manufacturers prepare existing and future production facilities for this dynamic phase and dramatically shortened innovation cycles?

Turck has the answer: with smart automation technology, data-driven process optimization and flexible production systems. RFID identification technology, for example, helps to increase the yield of existing plants and process safety and product quality at the same time. Smart automation with condition monitoring indicates problems early on and thus allows the implementation of predictive maintenance measures, thus increasing availability and the overall efficiency of a plant (OEE). Decentralized automation technology with robust cabinet-free IP67 systems simplifies the building of modular production plants for the later regrouping of machinery or the relocation of capacities.

Three Loading Columns for Production Efficiency

The digitization of automation and production technology offers many benefits. Use this to improve the output and quality of existing plants – and set the benchmark for battery cell production plants.

Production traceability

The energy density of batteries can be compared to explosives. Faulty batteries can thus be quite dangerous and risky. Production that tracks and documents, every raw material, every product and every production step guarantees battery cells of the highest quality. Error-free production can be proven by track-and-trace systems in cases of doubt.

Turck has almost 20 years of experience with HF and UHF RFID solutions in the production environment. Hardly any other automation supplier can offer such a comprehensive RFID range and unique technologies such as HF bus mode.

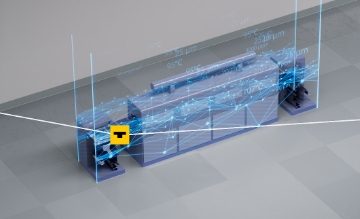

Overall equipment effectiveness (OEE)

The costs of a product and the profitability of a production process heavily depend on the availability of its production equipment. This is another reason why increasing the overall efficiency of equipment is a key goal in battery manufacturing. The goals are to minimize unplanned machine downtimes and eliminate material bottlenecks.

Turck automation technology enables you to master both challenges: You can extensively monitor machine states to plan predictive maintenance, while RFID identification technology improves your database for material procurement.

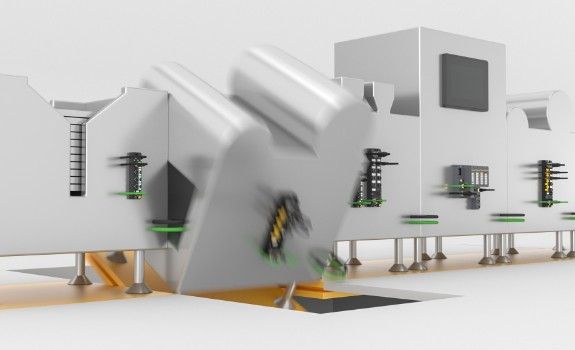

Flexible production

The number of battery cell types is also increased with the different battery applications. Currently built production equipment should therefore be prepared for future adaptions, both mechanically and in terms of automation. Modular plant concepts are the royal road to greater flexibility.

Decentralized I/O and control solutions in IP67, combined with flexible and fast Industrial Ethernet communication, allows plant modules to be quickly re-arranged. Controlled by decentralized PLCs and safety controllers, factory acceptance tests of new plant modules can already be carried out at the manufacturer, thus shortening commissioning in the entire plant at the user's site.

IIoT Solutions for Battery Manufacturing

Turck has developed unique technologies and solutions to put your production at the forefront of your industry.

Webinar: Data-driven battery production

Proven Solutions for Better Battery Production

Turck has been a worldwide partner for battery manufacturers for a long time. We have developed a large number of solutions in the course of these partnerships that can also bring your production forward – see for yourself.

Selected Products for the Production of Battery Cells

Condition Monitoring

Condition monitoring sensors detect critical environmental conditions, such as humidity, temperature, and vibrations. And the devices from the CCM product series evaluate the data, using the customer's own programming if required.

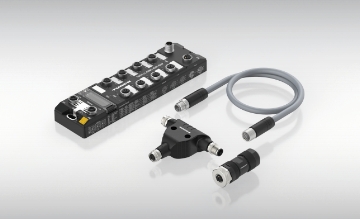

Complete M12 Power Portfolio

Our I/O modules for Ethernet (PROFINET, EtherNet/IP, Modbus TCP, EtherCAT) are equipped with M12 Power supply units as standard. They round off our M12 Power range of junction boxes, connection cables and IP67 power supplies.

Edge Controller and I/O Solutions

Turck provides one of the most diverse ranges of edge controllers, namely controllers with cloud connections, with or without displays. Our IP20 or IP67 I/O solutions also bring logic to the field, fully replacing the PLC or taking over some of its functionality.

RFID Readers, Read/Write Heads and Interfaces

Turck's identification systems offer suitable solutions to meet all performance, location and distance requirements. Few other automation partners can handle both production and logistics IDs equally well.

Safety Modules with Integrated Safety Controllers

IP67 block I/Os enable safety functions to be implemented without switch cabinets. Safety applications can be tested offline using their safety controller and controlled in a decentralized way during live operation.

Smart Sensors

Turck's inductive proximity switches are considered to be the de facto standard for bodywork construction in the automotive industry. Our encoders, photoelectric sensors and the Fluid+ series of sensors show that this good reputation is well-deserved.

Ask Our Experts

We have experts in battery cell production in the most important markets worldwide. Do not hesitate and ask about our solutions to your particular challenge.

Our expers (f.l.t.r.):